Advanced Precision Stamping & Fine Blanking for Automotive Components

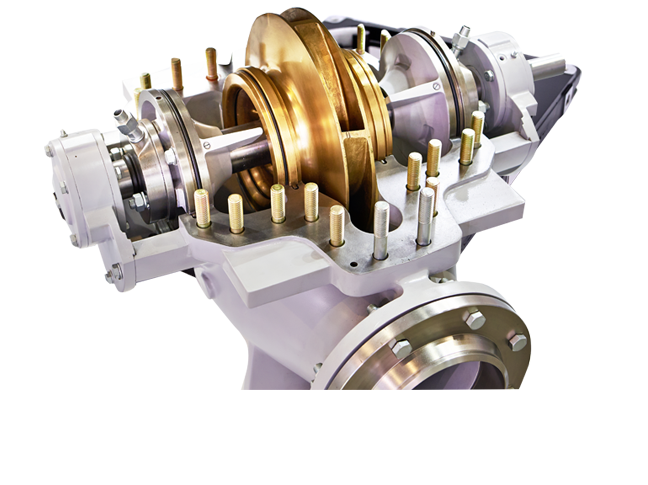

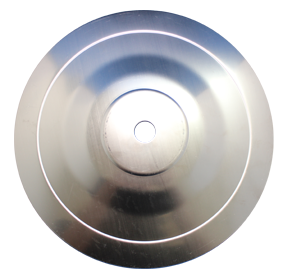

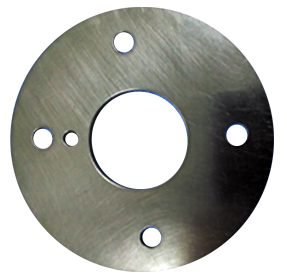

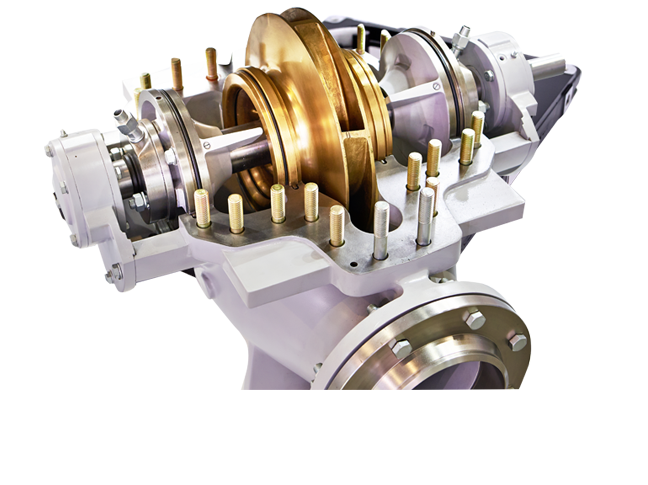

CFTC Group, a top-tier precision stamping company and one of the leading fine blanking parts manufacturers, provides specialized metal stamping services for the motor industry. Our expertise in fine blanking components supports critical applications in powertrains, timing gaskets, side plates, and valve plates, ensuring high performance and precision for motor systems.

Equipped with 16 fine blanking machines (from Feintool, Switzerland, and Mori, Japan) and 12 precision grinding and welding systems, CFTC’s production facilities span over 75,000 square meters across both sides of the Taiwan Strait. With 61 stamping production lines, ranging from 60 to 1000 tons, and an automatic storage system of 3,000 units, we provide end-to-end production for fine blanking components and precision parts manufacturing. This comprehensive setup enables CFTC to deliver unmatched quality and efficiency in metal stamping services.

Complete One-Stop Solution for Precision Stamping and Fine Blanking

As a recognized precision stamping company, CFTC offers a one-stop production process, covering all stages of precision stamping, precision grinding, CNC machining, deburring, heat treatment, and cleaning. Our capabilities include independent mold development and high-speed mold production, ensuring consistent quality and reliable testing for fine blanking parts. With an annual production capacity of 3 million units, CFTC is a reliable partner for high-end precision stamping and metal stamping services, supporting the demands of the motor industry with excellence.