Precision Stamping for Hydraulic Pumps & Industrial Applications

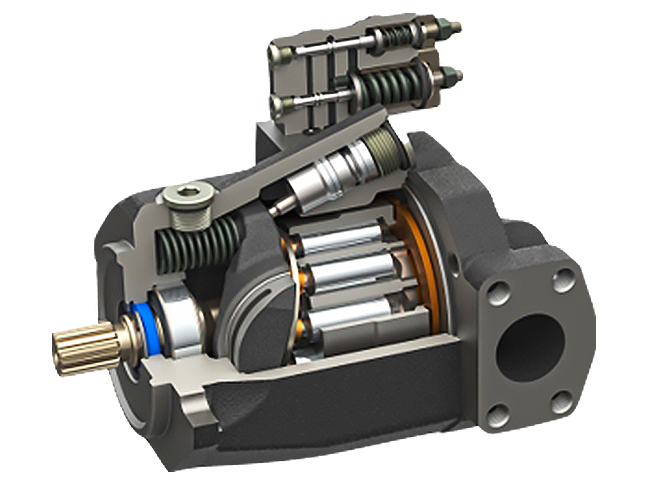

Are you looking for a trusted industrial stamping & manufacturing company? CFTC stands as a leading global provider among fine blanking parts manufacturers, specializing in precision metal stamping services. Our expertise extends to critical hydraulic components like plunger pumps and hydraulic pumps (hydraulic power components), often utilized in high-pressure, high-flow applications, including hydraulic presses, construction machinery, and marine equipment. These components provide essential flow adjustments and high-efficiency performance required by demanding industrial systems.

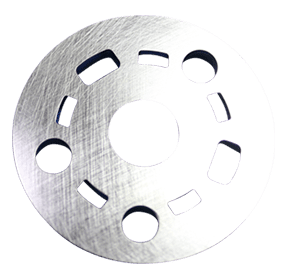

High-Strength Bimetallic Components: Precision Stamping for Wear Resistance & Clean Edges

Our unique bimetallic production process, combining copper and steel, produces components that meet stringent standards for both wear resistance and strength. As a leader among fine blanking components manufacturers, CFTC applies fine blanking to achieve extremely clean and precise edges, essential for parts with exact tolerances or complex shapes. This process is particularly suited for bimetallic components, ensuring they meet the highest quality standards while minimizing the need for additional processing.

Fine Blanking for High-Precision Metal Stamping Services

Fine blanking is one of our specialized metal stamping services that delivers superior edge quality and precision, ideal for applications requiring intricate geometries. CFTC’s fine blanking process enhances efficiency and quality, providing fine blanking components that meet the demands of industries where durability and precision are paramount. As one of the top fine blanking parts manufacturers, we are committed to delivering high-quality parts with minimal secondary processing, ensuring optimal performance and reliability in the hydraulic pumps industry.